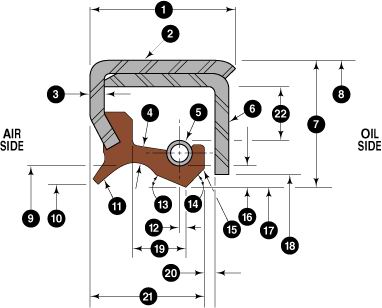

Garter

Spring – The garter spring is a helically

coiled wire with its ends connected to form a ring. It

is used to add

a constant load to the seal’s primary lip. The garter

spring compensates for the loss of lip force against the

shaft as the elastomer relaxes when exposed to elevated

temperatures over time. The garter spring is considered

essential when sealing low viscosity fluids or shafts rotating

at high RPM. (See chart page 10.)

Case – Metal

stamping to which the elastomer is bonded.

Seal

Width – Overall width of the seal.

Case

Thickness – Metal case thickness varies

based on size and application of seal.

Lip

Flex Thickness – The thickness of the primary lip

section between the spring and the case that flexes outward

when the shaft is installed through it. The thickness of

the flex section helps energize the lip against the shaft

and governs the seal’s resistance to pressure. It

also contributes to the amount of friction between the

lip and the shaft.

Inner

Case – A metal stamping incorporated within the outer

case to provide additional seal rigidity and to protect

the elastomeric lip during seal installation.

Radial

Section with Free Lip – The cross-section of the

seal measured from the outside diameter to the primary-lip

inside

diameter.

Outside

Diameter – The diameter of the seal’s outer

surface which is press-fit into its mating bore. This surface

provides the static sealing interface to the housing, as

well as mechanically locking the seal in the assembly.

Lip

Clearance Diameter or Heel Diameter – The seal’s

inside diameter which provides clearance with the shaft.

It is the surface of the seal’s inside diameter that

determines the flex section.

Dirt

Lip Diameter – The inside diameter of the air side

lip that is typically designed for only net contact with

the shaft to prevent additional frictional heat. This diameter

can be designed with shaft interference for increased dirt

exclusion at the cost of increased frictional heat.

Dirt

Lip – The dirt lip is located at the air side of

the seal to prevent contaminants from entering the assembly.

It is also used to retain grease.

R

Value – The axial distance between the lip contact

point and the centerline of the garter spring. The garter

spring is typically offset to the air side of the lip 0.25

to 0.75mm for optimum sealing.

Barrel

Angle – The angle between the seal centerline and

primary lip’s conical surface to the air side of

the seal. This angle should be approximately 30 degrees

to allow a meniscus of fluid to be retained between the

lip and the shaft. A properly designed seal rides on this

meniscus rather than the shaft itself to reduce friction

and wear.

Scraper

Angle – The angle between the seal centerline and

primary lip’s conical surface to the oil side of

the seal. This angle is typically 55 degrees and helps

to form the meniscus of fluid on which the seal contact

point rides.

Primary

Seal Lip – The lip located on the oil side of the

seal. It performs the principle dynamic sealing function.

If the seal utilizes a garter spring, it will be located

on this lip.

Head

Thickness – Head thickness is the radial distance

between the primary lip’s contact point and the spring

pocket.

Primary

Seal Lip Inside Diameter – The smallest diameter

of the seal primary lip. This diameter is stretched onto

the

shaft energizing the elastic properties of the lip creating

the dynamic interface for the assembly.

Inner

Case Inside Diameter – The smallest diameter of the

inner case designed to protect the lip from damage. It

protects against the spring becoming dislodged at assembly

and guarantees clearance between the inner case and the

shaft.

Beam

Length – The axial distance between the lip contact

point and the base of the lip flex thickness. Short beam

lengths provide greater resistance to internal pressure.

Longer beam lengths provide more flexibility to better

follow shaft eccentricities at higher RPM.

Axial

Lip Clearance – The axial distance between the

primary seal lip and the inside wall of the inner case.

This dimension is critical to ensure clearance between

the case and the lip after being installed over the shaft.

Lip

Length – The primary seal lip’s overall length

measured from its air side face to the back of the seal.

Radial

Spring Clearance – The radial distance from the outside

diameter of the garter spring to the inside wall of the

seal’s outer case. This clearance is important to

ensure free movement of the lip. |